ᅳ

Plastic: The “Villain”

ᅳ

Plastic has been hailed as the greatest invention of mankind. However, due to environmental pollution that occurs during manufacturing, landfill, and incineration, the world is now labeling it a calamity for humanity.

Did you know that the main raw material of plastic is oil? According to the World Economic Forum, about 4-8% of global oil consumption per year goes to plastic production; at this rate, it will account for 20% of oil consumption by 2050. The creation of plastics generates a huge amount of carbon.

In addition, plastics also emit a huge amount of greenhouse gases through transportation and disposal. As we all know, plastic is not biodegradable, so if plastic gets into the soil, rivers or oceans, it means that purification is impossible.

ᅳ

Will We Tax Plastic From Now On?

Policy to Wean Ourselves Off Plastic

ᅳ

As ‘carbon neutrality’ is emerging as the top priority of the international community to combat climate change, major countries are announcing policies related to plastic regulation and recycling.

The front runner is Europe. The European Union (EU) introduced a plastic tax in 2021. By 2030, all plastic packaging materials used in the EU market will be reusable or recycled. In order to realize this, a tax of about 0.8 euros (~960 won) per kilogram of non-recycled plastic packaging waste is being imposed. It also includes the development of recyclable plastics and a ban on the use of microplastics. This means that the plastics policy, which has been created in the framework of a linear economy hinging on “production → consumption → discharge → collection → disposal,” is fundamentally changing.

China has decided to ban the use of non-degradable plastic bags by 2026, and Japan has decided to double plastic recycling by 2030. Korea plans to limit the use of petroleum-based bioplastics by 2030 and replace them with pure bioplastics by 2050.

ᅳ

Vinyl Made from Sugar Cane and Corn Stubble?

What is Called “Bioplastic”

ᅳ

Riding on this plastic regulatory flow, plastic bags and cups with “biodegradable” or “environmentally friendly” marks are putting down roots on all sides. They are made from natural ingredients, and they decompose in nature after use and discarding.

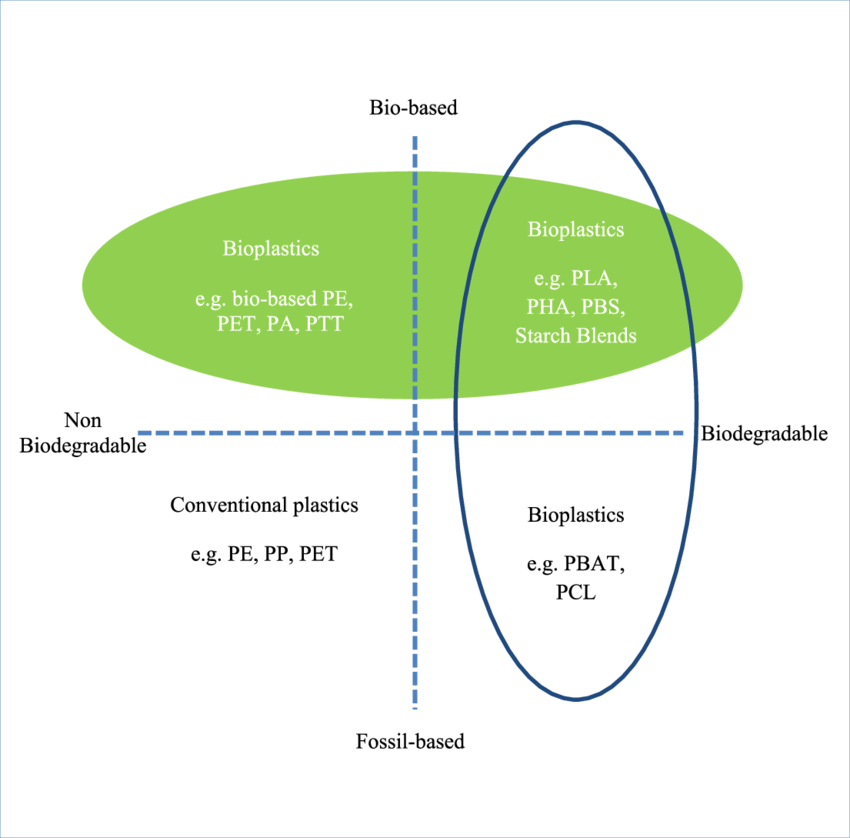

Bioplastics can be broadly classified into "whether they are biodegradable after use" and "made from natural raw materials." Bioplastics are referred to by several terms, such as "biodegradable" plastics and "natural" plastics, depending on where the emphasis is placed.

○ Is it biodegradable?

When more than 90% of the plastic is decomposed into water and carbon dioxide within 6 months at a temperature of around 58℃, it is called "biodegradable plastic."

There are microbial synthesis systems such as PHA and PHB, natural product synthesis systems PLA, and petrochemical synthesis systems PBAT and PCL. Namely, PBAT and PCL are bioplastics as they are biodegradable though they are made from chemical ingredients.

On the other hand, plastics that decompose more than 60% within 6 months are called "oxidative biodegradable plastics."

○ Is it made from natural (bio) raw materials?

Plastics made from plants such as corn stalk and sugar cane are called biomass plastics.

Bioplastics that we readily encounter in daily life are biomass plastics made from corn stalk or sugarcane. Compared to other bioplastics, the barrier to permeation is low and production cost is low, so it is widely used. However, since it is weak against heat and moisture, it is mainly used to make disposable bags, packaging materials, cups, and tableware.

A bioplastic container launched by a domestic delivery firm (Source: Baemin Sanghoe)

The fact is, not all biomass plastics are biodegradable. However, they have the advantage of reducing carbon emissions compared to conventional plastics in the process of manufacturing and incineration.

In summary, making a plastic item with natural ingredients doesn't necessarily mean it's biodegradable, and just because it's biodegradable doesn't mean it's based on natural ingredients. Did you catch the distinction?

On the other hand, there is a controversy that bioplastics are greenwashing. In November 2015, the United Nations Environment Program (UNEP) published a report stating that “even if the use of biodegradable plastics increases, environmental pollution will not decrease significantly.” This is because “biodegradable plastics decompose only when the temperature exceeds 50℃, but in a natural environment, it is rare that the temperature exceeds 50℃”.

http://www.sunhakpeaceprize.org/en/news/issue.php?bgu=view&idx=586

(Go to the Sunhak Peace Prize Peace Issue on Green Washing)

ᅳ

There are even real bioplastics

that are 100% biodegradable!

ᅳ

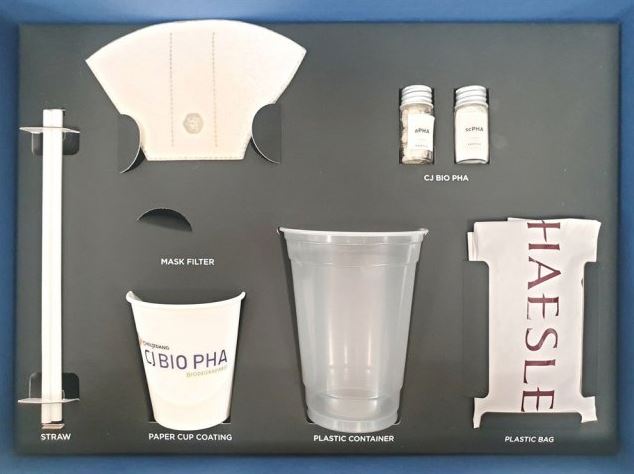

(PHA plastic product of CJ CheilJedang)

There are also ‘real’ eco-friendly bioplastics that are made through microbial fermentation and are biodegradable in nature. It is a plastic made from polyhydroxyalkanoate (PHA).

PHA is a high-molecular substance produced by microorganisms after consuming plant-derived ingredients. It has soft properties similar to rubber. With these qualities, various items such as packaging materials and plastic bags can be made from it.

PHA is 100% biodegradable. Because it is a material made by microorganisms, it is 100% biodegradable in all natural environments as long as there are microorganisms. It is biodegradable even in the sea, so it is expected to be a key to solving the marine plastic problem.

(Biodegradable alcohol bottle from a liquor company affiliated with Danimer Scientific)

PHA is a material that is harmless to the human body and even induces carbon reduction, so its added value is very high. Currently, it is known that there are only three PHA companies in the world with synthesis technology and production capacity.

This is because it is a technology with very high barriers to entry. Currently, Danimer Scientific in the U.S., CJ CheilJedang in Korea, and Kaneka in Japan possess this technology.

Therefore, it is urgent to have economic feasibility due to high production cost. Statista, a company specializing in industry statistics, predicts that the global PHA market will grow from $62 million in 2020 to $908 million in 2025.

ᅳ

Bioplastic production on the rise

ᅳ

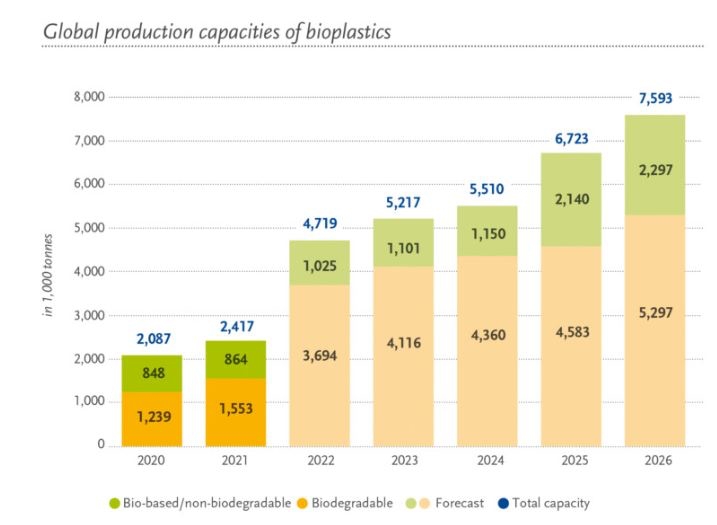

Meanwhile, the production of bioplastics is steadily increasing. While the demand for biodegradable plastics is increasing due to the global tightening of regulations on the use of disposable products, the global bioplastics market is expected to grow from KRW 12 trillion in 2021 to KRW 34 trillion in 2026, growing at a CAGR of 23%.

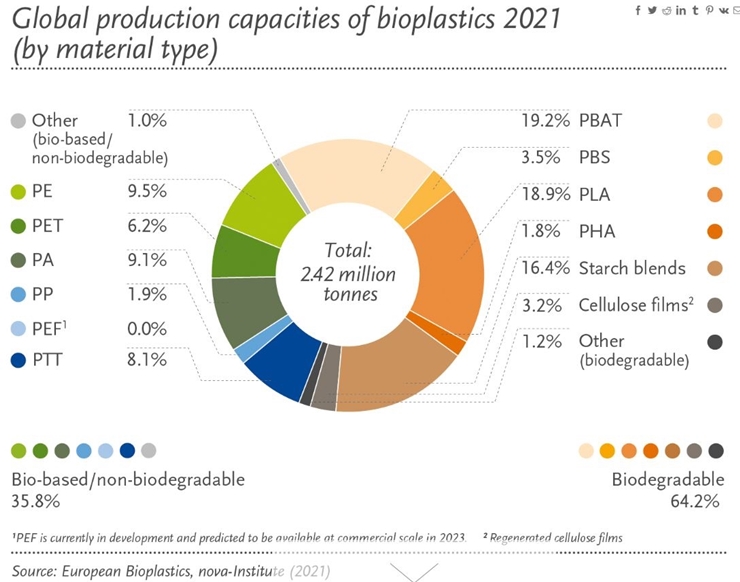

It is estimated that 367 million tons of plastic was produced worldwide in 2021. Among them, bioplastic accounts for less than 1%, or about 2.42 million tons, and it is expected to increase gradually to about 7.59 million tons, or 2%, by 2026. (Source: European Bioplastics Association)

(Trends in bioplastic production, data from European Bioplastics)

*Green: bio-based + non-degradable plastic, orange: biodegradable plastic

https://www.european-bioplastics.org/market/#

(Bioplastics Market Analysis Detailed Data)

(Bioplastic production in 2021 by material type)

ᅳ

Bioplastics, the remaining task...

ᅳ

As mentioned earlier, the most commonly used bioplastic around us is PLA plastic made from corn-derived ingredients, and it is currently being applied to various items such as coffee filters, bags, tableware, and textiles.

Here's a question for you! ~ Do you separate PLA tableware (biodegradable plastic) left after ordering food for delivery from regular plastic? Perhaps the answer is NO. Perhaps it was a bioplastic, so it was thrown away along with other plastics, comforting yourself that it would be of some benefit to the environment.

This is where the problem arises. Since biodegradable plastics lose their properties when mixed with chemical plastics, they cannot be recycled when mixed with other plastics.

So what should we do? PLA plastics must be disposed of separately from general plastics. Thus it is necessary to add a “bioplastic sorting space” to the recycling collection center and dispose of it separately. This is not the end. PLA-based plastics are difficult to decompose in their natural state, so it is necessary to create a separate landfill facility with biodegradation conditions.

Difficult challenges pile up one after another. After all, the plastic problem is fundamentally intertwined with the disposable culture. To solve this problem, together with changing materials, we will all need to make efforts to reduce the absolute consumption of plastics.

Written by Sharon Choi

Director of Planning

Sunhak Peace Prize Secretariat